British-milled excellence

At Lovat Mill in the Scottish Borders, age-old skills and craftsmanship are blended with forward-thinking innovation. The result? A traditional fabric with enduring appeal and standout performance that is synonymous with the British countryside.

From the land comes the cloth

Nestled in the heart of the Scottish Borders, Lovat Mill is renowned as the Home of Tweed, carrying forward a legacy of craftsmanship that spans generations. With a deep-rooted heritage in textile production, the mill expertly weaves premium fabrics using British wool, time-honoured techniques and modern innovation. Committed to sustainability, Lovat Mill prioritises natural fibres, responsible sourcing, and environmentally conscious production.

How is tweed made?

At Lovat Mill, the tweed-making process comprises a series of complex and intricate steps. Precision and patience are key to each. Here’s an overview of how tweed is made:

Why Lovat Mill tweed?

-

Heritage and tradition

Woven in Scotland where tweed has a rich history.

-

A product of craftsmanship

Made by artisans using time-honoured techniques

-

Sustainability

Natural fibres and ethical production are central to the tweed-making process

-

Natural performance

Made from British wool which is soft, durable, and breathable.

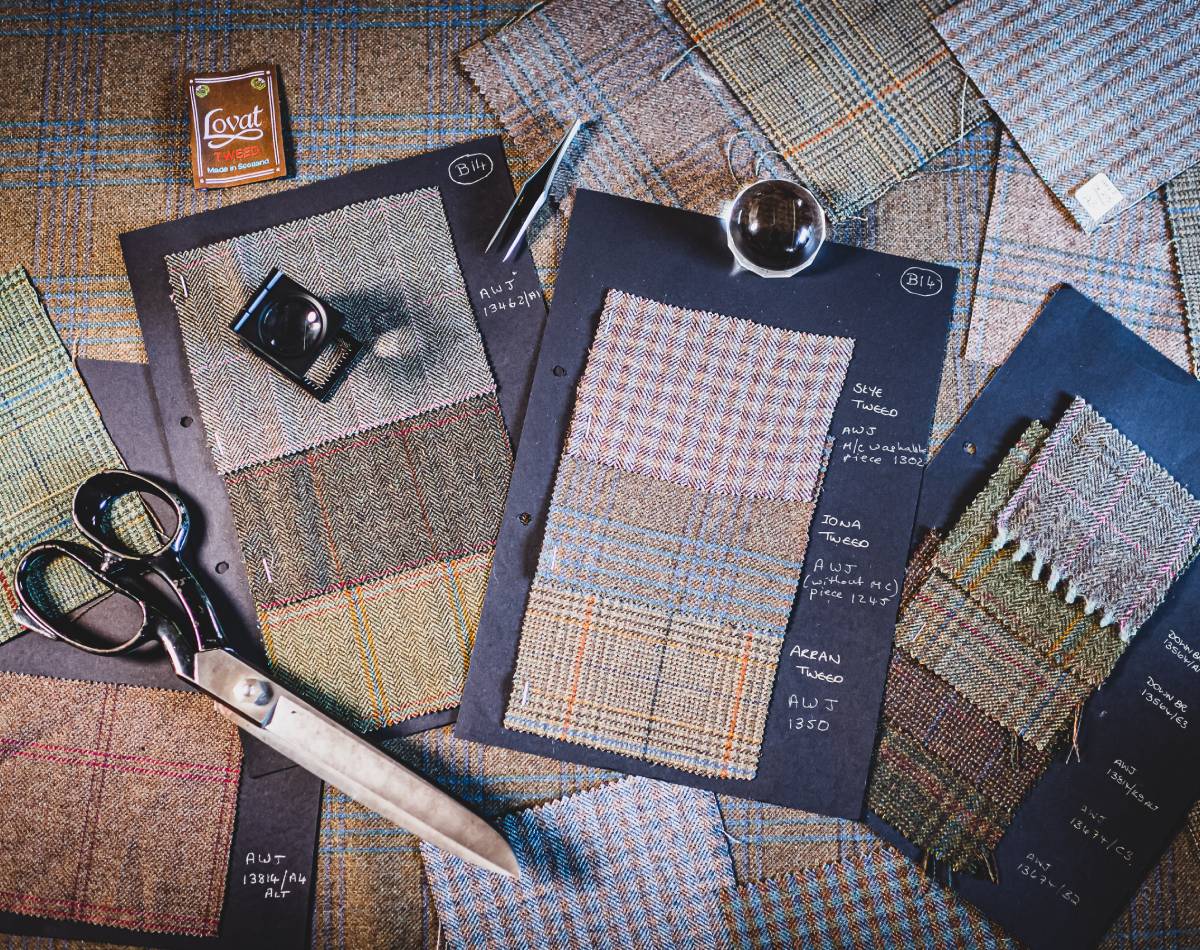

Schöffel Country x Lovat Mill

"Creating the fabric for our tweed collection at Schöffel Country is a hugely collaborative process," explains Marcus Janssen, the executive director of Schöffel Country. "We all start by sharing our colour, pattern, and trend ideas. The team at Lovat Mill oozes creativity and inspiration, so the process is extremely enjoyable. What really fascinated me was how adding a single thread or two of new colour can transform the tweed into something completely different. If you look at even the most sombre-coloured tweed through a magnifying glass, you will be amazed by how many colours are woven into each thread, giving the tweed depth and lustre. It really is magical.”